In the era of high-speed connectivity, superior RF performance begins with precision engineering. Equipped with electromagnetic & electrical simulation, modeling analysis, mechanical simulation, 3D modeling, and engineering drafting, we deliver highly reliable RF connector solutions for global industries.

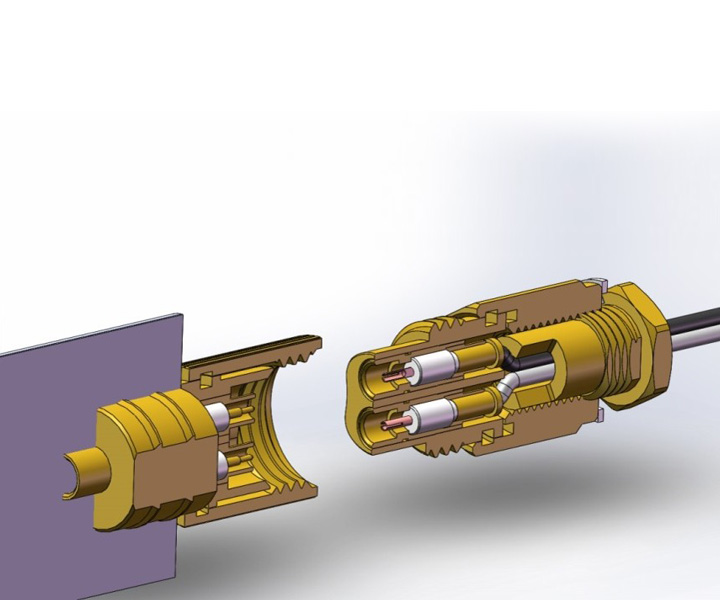

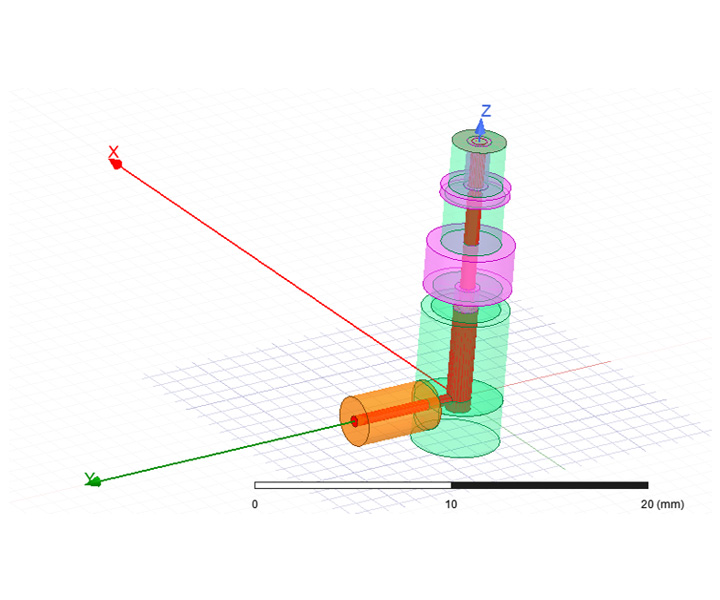

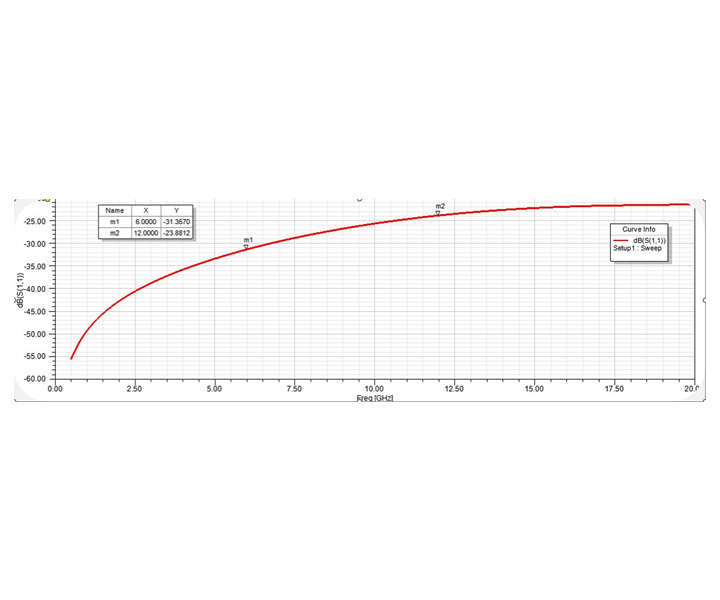

▌ EM & Electrical Performance Simulation

Advanced simulation predicts signal integrity, impedance matching, and high-frequency loss, ensuring stable transmission in complex environments.

▌ Multi-Dimensional Modeling & Validation

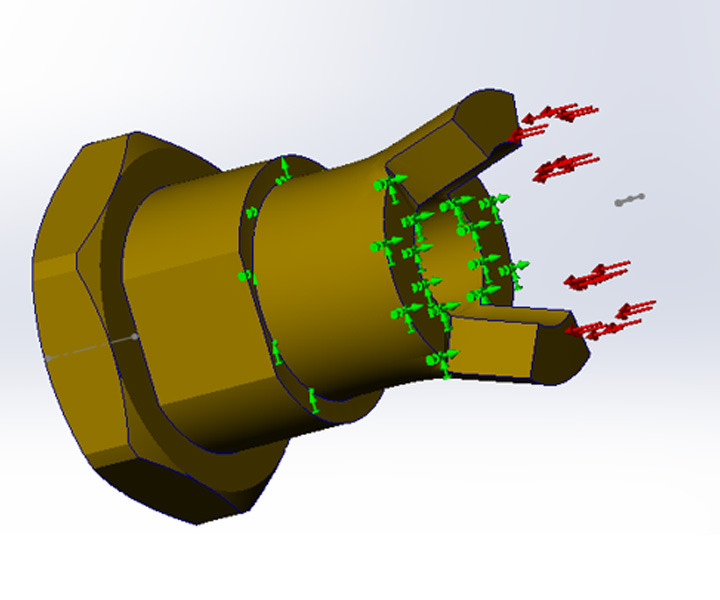

From structural modeling to mechanical stress analysis, we simulate durability under extreme conditions, optimizing designs for vibration resistance, corrosion protection, and critical performance.

▌ Seamless Digital Design to Manufacturing

Parametric 3D modeling and ISO-compliant engineering drawings bridge design and production, reducing development cycles and iteration costs.

Engineering Excellence. Connected Reliability.

—We empower 5G, aerospace, medical devices, and beyond with data-driven RF solutions.

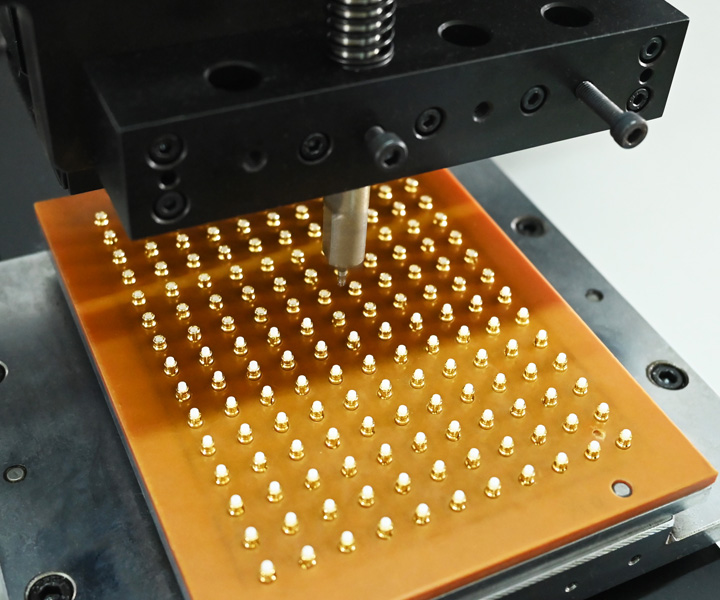

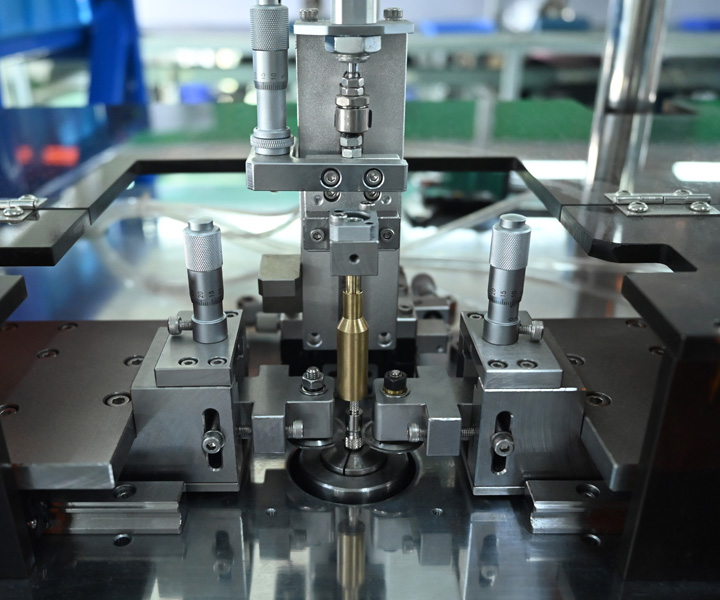

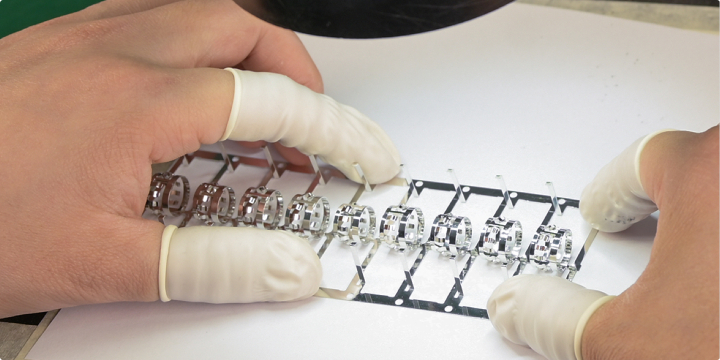

From CNC machining to automated assembly, we combine advanced equipment with strict quality control to deliver high-performance RF connectors and cable assemblies. Backed by a vertically integrated production system, we ensure precision, efficiency, and scalability for global industries.

Shintonic utilizes high-speed precision stamping processes to manufacture metal contacts and shielding components for RF coaxial connectors. Our stamping technology guarantees ±0.01mm tolerances, excellent conductivity, and durability, meeting stringent requirements for high-frequency signal transmission.

Our injection-molded insulator components are designed to minimize signal loss and enhance dielectric properties in RF coaxial connectors. Using high-performance materials like PTFE, PEEK, and LCP, we ensure thermal stability and mechanical strength in demanding environments.

Shintonic manufactures durable connector housings and structural parts through precision die-casting. Our process guarantees high strength, corrosion resistance, and superior EMI shielding—ideal for industrial, automotive, and aerospace RF solutions.

Engineered for 5G, military/aerospace and other high-end applications, our multi-axis CNC machining centers deliver exceptional ±0.005mm tolerances. We specialize in processing stainless steel, titanium alloys, beryllium copper, and brass materials with premium electroplating surface treatments to meet the extreme precision requirements of RF connector core components.

Shintonic Electronics has the ability to design, process, and assemble high-precision segments. We design a series of high reliability low-voltage terminals for our customers. In terms of product size and coating treatment, Xiante Electronics has always adhered to high standards and strict requirements, in order to ensure that every product can meet the customer’s standards.

We have a complete set of testing equipment for coating thickness detection, smoke testing, welding testing, etc. From incoming material storage to finished product testing, we strictly monitor product quality at every stage.

1255Huayuan Road, ZhangPu Town, Kunshan City, Jiangsu Province, China

PHONE: +86(512) 5729 1216

EMAIL: sales@shinto-electronics.com

© 2025 Copyright reserved by Shintonic Electronics. The website supports Sixe Network